OFR-MW

DESCRIPTION

OFR-MW is a nanotechnological additive for emulsifiable cutting oils.

OFR-MW is an ester-based nanotechnological additive to be added to emulsifiable oil and is compatible with all types of oils.

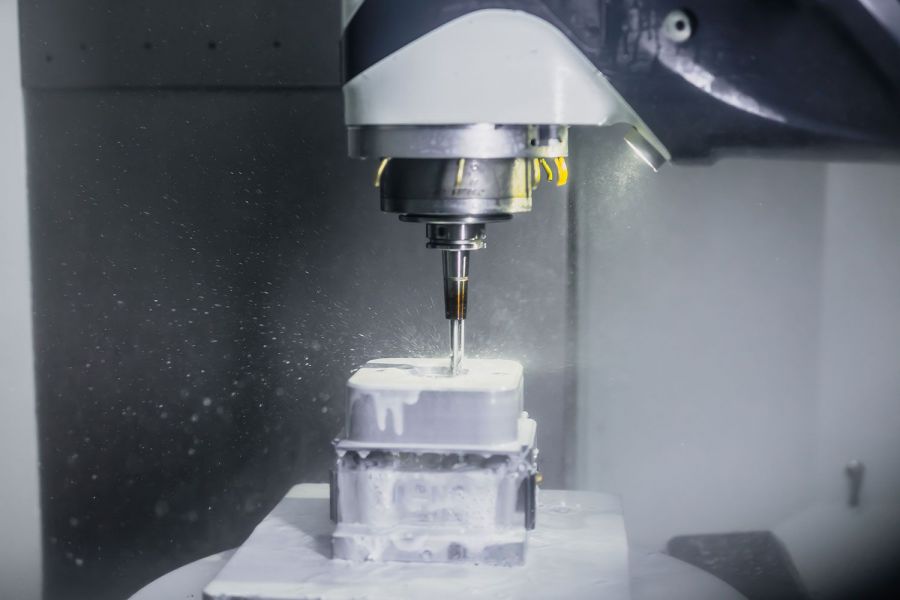

OFR-MW increases the lubrication and cooling characteristics of the emulsified solution (water + oil) in all stages of machining: turning, milling, drilling, etc.

OFR-MW has antibacterial capabilities.

Main properties

CHARACTERISTICS

- Ester base additive

- Reduces friction and wear of cutting tools

ADVANTAGES

- Good compatibility with all types of oils and low environmental impact

- Longer life: up to doubling of tool life

- Reduction of machine stops for tool replacement

- Possibility to increase the processing speed

- Better worked product surface quality

- Reduces electrical absorption

BENEFITS

- Can be used with both synthetic and mineral oils

- Cost reduction

KEY BENEFITS

OFR-MW improves the properties of the emulsified oil, thanks to the presence of nanoparticles:

- better wettability of the emulsion

- better thermal and lubricating properties

- reduction of the friction force during machining with consequent improvement in chip removal

- reduction of the roughness of the machined surface

AVAILABLE FORMATS

OFR-MW is supplied in:

- 25L tanks

- 220L drums

Storage and shelf life

OFR-MW must be stored at temperatures between +5°C and +30°C. The estimated shelf life is 12 months (in unopened package). Do not leave the package open and do not let the product freeze.

Usage tips

OFR-MW is an additive to be added to the lubricant oil, before preparing the emulsion with water:

- put 80g of OFR-MW for every 1kg of lubricant oil.